Crash

Cook

One only has to use one of these offset smokers a couple of times to realize they're very inefficient. The fire in the SFB has to be hot enough to melt metal in order to maintain 250* in the smoke box.

One solution would be to insulate the smoke chamber. A web search revealed that the most popular method is to cover the smoke box with a welders blanket and/or line the bottom of the barrel with lava rocks.

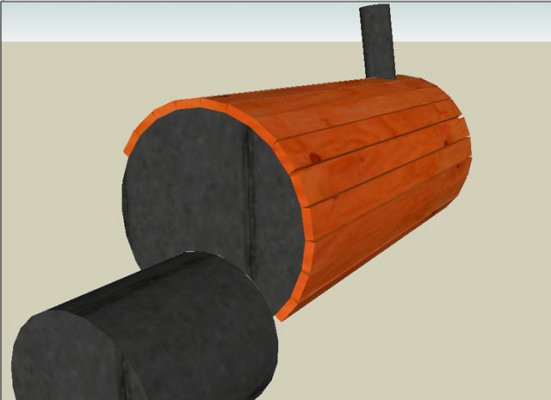

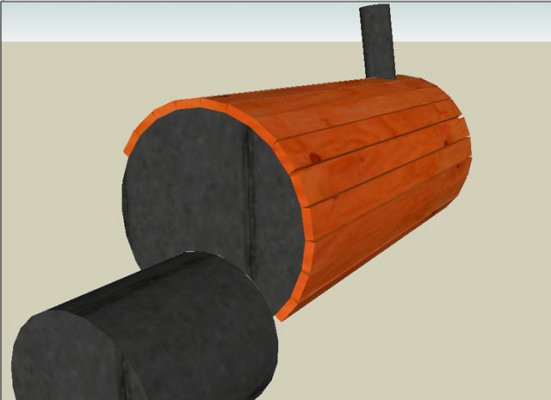

This is what I came up with:

Line the outside with 3/4" slats of wood, perhaps Cedar. Bond the wood to the barrel with heat resistant adhesive. Anyone know a good cement for such an application?

One drawback to this solution is that the smoke box could no longer be used as a grill.

------------

Another solution would be to help the heat move from the fire box to the smoke box.

I noticed that stirring the coal bed to shake off ash, helped the air move through the coals better and thus raising the temperature in the smoke box.

On longer smoking sessions however, I noticed that by doing so, the ash drawer filled up quickly and air couldn't pass through the bottom of the coals choking the fire.

Since the grate that holds the coals sits on/in the ash drawer, removing the ashes is impossible. To keep the fire going, I had to constantly insert something through the flue opening to make a tunnel for the air to pass.

This is what I propose to solve the problem:

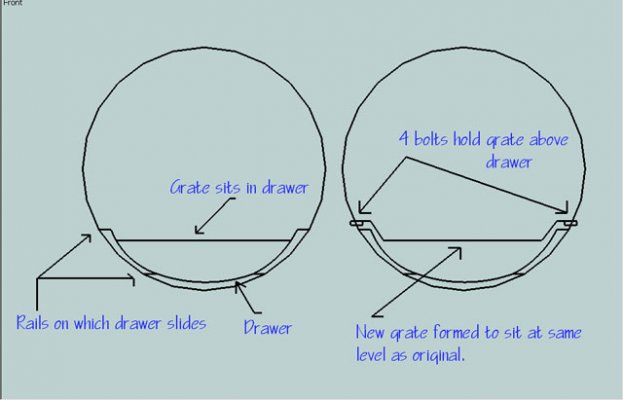

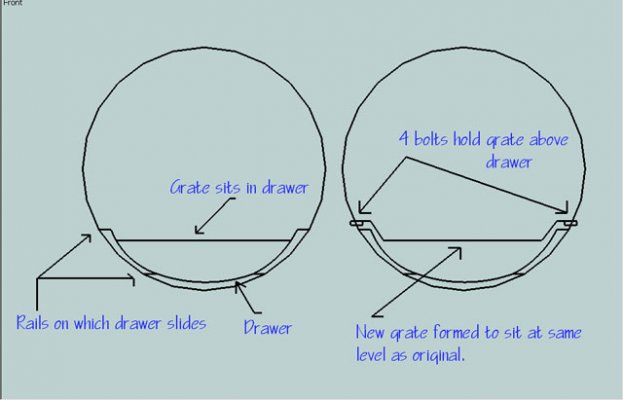

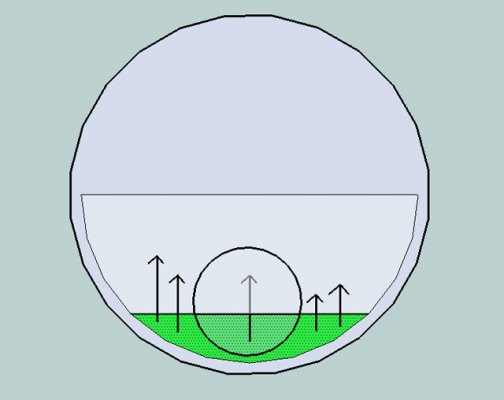

The diagram on the left represents the Chargriller SFB as it is. The one on the right shows the modification. By having the grate sit on four bolts fixed to the SFB wall, allows one to remove and empty the ash drawer leaving the charcoal grate and coals in the box.

I haven't made either modifications yet (did I mention I'm lazy) . Please let me know what you think.

. Please let me know what you think.

If you have done any mods or have ideas for any, please share them with us.

One solution would be to insulate the smoke chamber. A web search revealed that the most popular method is to cover the smoke box with a welders blanket and/or line the bottom of the barrel with lava rocks.

This is what I came up with:

Line the outside with 3/4" slats of wood, perhaps Cedar. Bond the wood to the barrel with heat resistant adhesive. Anyone know a good cement for such an application?

One drawback to this solution is that the smoke box could no longer be used as a grill.

------------

Another solution would be to help the heat move from the fire box to the smoke box.

I noticed that stirring the coal bed to shake off ash, helped the air move through the coals better and thus raising the temperature in the smoke box.

On longer smoking sessions however, I noticed that by doing so, the ash drawer filled up quickly and air couldn't pass through the bottom of the coals choking the fire.

Since the grate that holds the coals sits on/in the ash drawer, removing the ashes is impossible. To keep the fire going, I had to constantly insert something through the flue opening to make a tunnel for the air to pass.

This is what I propose to solve the problem:

The diagram on the left represents the Chargriller SFB as it is. The one on the right shows the modification. By having the grate sit on four bolts fixed to the SFB wall, allows one to remove and empty the ash drawer leaving the charcoal grate and coals in the box.

I haven't made either modifications yet (did I mention I'm lazy)

If you have done any mods or have ideas for any, please share them with us.

I let the wood burn down to just about coals and closed the lid. Sort of eliminating having a separate fire box.

I let the wood burn down to just about coals and closed the lid. Sort of eliminating having a separate fire box.